Apple II Plus Rev 7 RFI: Difference between revisions

No edit summary |

|||

| Line 15: | Line 15: | ||

The Apple II Plus Rev 7 RFI Kit is a total of 2160 pads, or "solder joints". It takes about 5 hours to fully assemble the kit if you have a decent iron, flux, and solder. | The Apple II Plus Rev 7 RFI Kit is a total of 2160 pads, or "solder joints". It takes about 5 hours to fully assemble the kit if you have a decent iron, flux, and solder. | ||

To assemble your kit we recommend adding parts in groups and then soldering them. This will be the fastest way to assemble the PCB rather than adding one part at a time then soldering it. For example, start with the IC sockets. Each time a socket is added you can most simply bend over one pin on each side to help hold the socket to the PCB which allows the PCB to be turned over and prevents parts from falling out. The sockets are all the same thickness as well. If you solder on a flat surface then this will also help hold all the sockets flat to the PCB. Once the sockets are done then add the passive parts like caps and resistors. Again, bending pins and group loading and soldering. End with the larger parts, like jacks, and finally the slots. Don't bend over these parts pins/legs as they will be too hard. You will need to hold them in place as you solder a few pins before you can group solder. | To assemble your kit we recommend adding parts in groups and then soldering them. This will be the fastest way to assemble the PCB rather than adding one part at a time then soldering it. | ||

* For example, start with the IC sockets. Each time a socket is added you can most simply bend over one pin on each side to help hold the socket to the PCB which allows the PCB to be turned over and prevents parts from falling out. The sockets are all the same thickness as well. If you solder on a flat surface then this will also help hold all the sockets flat to the PCB. Once the sockets are done then add the passive parts like caps and resistors. Again, bending pins and group loading and soldering. End with the larger parts, like jacks, and finally the slots. Don't bend over these parts pins/legs as they will be too hard. You will need to hold them in place as you solder a few pins before you can group solder. | |||

To do: | To do: | ||

| Line 53: | Line 54: | ||

File:5-band_Resistor.jpg|5-band Resistor Markings | File:5-band_Resistor.jpg|5-band Resistor Markings | ||

</gallery> | </gallery> | ||

==Notices== | ==Notices== | ||

Revision as of 15:19, 5 March 2020

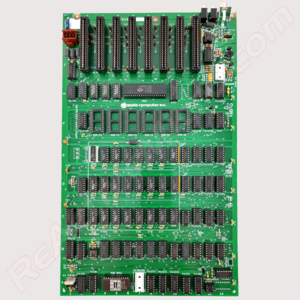

The Apple II Plus Rev 7 RFI project was started on April 20th, 2019 by Henry from ReActiveMicro, and was officially released on February 15th, 2020. This marks the first full computer project released by ReActiveMicro. The concept is a replacement board which is known good and fully tested, to be used as a replace for the original motherboard. This will allow the user a better experience and less issues moving forward. In contrast, most original motherboards now require constant maintenance in order to stay in a dependable running state. Compounding the situation, the original motherboard has low quality sockets, and old DRAMs and ICs which are power hungry and are well past their lifespan ratings.

Product Status: Actively sold by ReActiveMicro. RM is working on a "27-series" ROM version of this project. This page will be updated once the project has officially released.

Support: Post on the Discussion page (link above) or email ReActiveMicro Support.

Sales: Visit the ReActiveMicro Store.

Kit Assembly

The Apple II Plus Rev 7 RFI Kit is a total of 2160 pads, or "solder joints". It takes about 5 hours to fully assemble the kit if you have a decent iron, flux, and solder.

To assemble your kit we recommend adding parts in groups and then soldering them. This will be the fastest way to assemble the PCB rather than adding one part at a time then soldering it.

- For example, start with the IC sockets. Each time a socket is added you can most simply bend over one pin on each side to help hold the socket to the PCB which allows the PCB to be turned over and prevents parts from falling out. The sockets are all the same thickness as well. If you solder on a flat surface then this will also help hold all the sockets flat to the PCB. Once the sockets are done then add the passive parts like caps and resistors. Again, bending pins and group loading and soldering. End with the larger parts, like jacks, and finally the slots. Don't bend over these parts pins/legs as they will be too hard. You will need to hold them in place as you solder a few pins before you can group solder.

To do: Add note for RAs. Each has a 'dot' on the part and PCB to determine Pin1. RA01 has the Pin1 towards the slots. RA02 and RA03 have Pin1 towards the keyboard. RA01 has the silk screen border around all pads for the part. RA02 and RA03 has the silk screen border around only the inner 6 pads. Pin1 and Pin8 are outside the boarder.

Mention "A good loupe is recommended for helping identify and confirm parts, like the markings on some small caps. It also helps with soldering inspection. An illuminated 40 x 25mm and a 35 x 50mm loupe are well worth the investment and can be had for under $10 each on eBay."

C3 pic and note how to solder.

The parts included with your v1.0 kit and the PCB have basic labels. There are 2153 pads which need to be soldered. Those with intermediate knowledge should have little trouble assembling the kit from the labels on the parts, the bag, and the PCB. The images of the motherboard can also be used for reference or determine orientation, such as the diodes.

Some care does need to be taken when installing capacitors and diodes however.

If your kit includes Aluminum or Tantalum capacitors, or "caps" for short, then be sure to install them in the correct orientation. The PCB will be clearly marked with "+" signs for all cap locations when the orientation of the part matters, or a polarized part is normally used. Sometimes a non-polarized part is used in place of a polarized one and then its orientation does not matter. However install a polarized cap backwards and you will damage it. An Aluminum Electrolytic will have a strip pointing to the NEGATIVE end lead. A Tantalum Electrolytic will generally have a marking or stripe to denote (not always pointing to) the POSITIVE lead.

All caps will have value markings on them. "106" is 10uF, and "104" is .1uF. 10uF is also physically a lot larger than .1uF. This should help identify the two ceramic caps in the kit. They along with the Electrolytic caps can also clearly be seen in the assembled pic above.

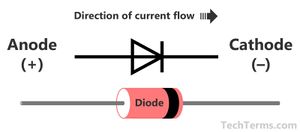

A diode also has a marking on it, and needs to be installed correctly as it only allows current to flow in one direction. Install it backwards and you won't usually damage it, however the circuit will no longer operate as intended. They can also clearly be seen in the assembled pic above.

- Here is an example pic of different caps, a diode, and their related markings.

-

Caps Markings

-

Diode Markings

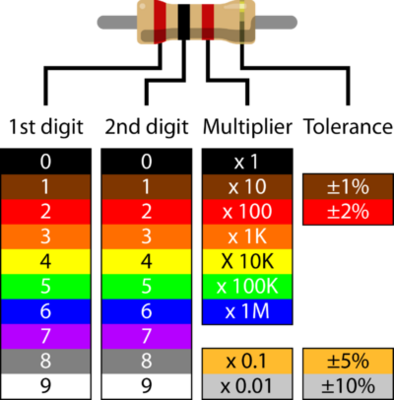

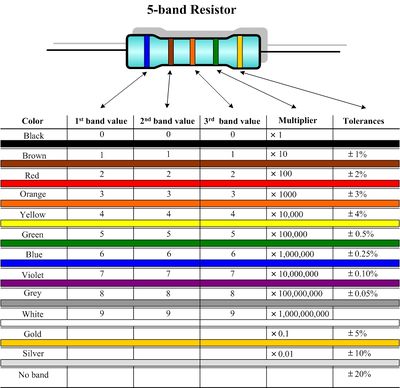

Your kit may include resistors. If so they could be the less precise "4 band" style which are typically 5% tolerance. Or the more precise "4 band" style which are typically 1% tolerance. Here are some charts on how to read them to help make matching locations on your PCB more easy.

-

4-band Resistor Markings

-

5-band Resistor Markings

Notices

- Character Generator / Video ROM (location A5)

- The ROM on the Rev 7 RFI board is pinned for a 2716 EPROM. A 2732 also works as however the A11 address line is held 'high' on the motherboard, so only the 'top' half of the ROM is used. When programming a 2732 the firmware is loaded in to address 0800-0FFF.

- Also note worthy is the speed of the ROM used. Some ROMs with an access time of 350nS tend to cause artifacts on the screen when used. 300nS or better should be used. It has been getting harder to find 250-300nS speed grades for 2716 EPROMs, so 2732 ROMs are used to address this issue.