Universal PSU Kit: Difference between revisions

No edit summary |

|||

| Line 46: | Line 46: | ||

== Reviews == | == Reviews == | ||

{{#ev:youtube|klCgfsONVLo|400|right|UltimateMicro Universal Apple II Power Supply Kit |frame}} | {{#ev:youtube|klCgfsONVLo|400|right|UltimateMicro Universal Apple II Power Supply Kit|frame}} | ||

On April 24, 2016 [[Joe_Strosnider|Joe Strosnider]] posted a review of The Universal PSU Kit. He gives some very good feedback and shows an installation on one of his own PSU Enclosures. | On April 24, 2016 [[Joe_Strosnider|Joe Strosnider]] posted a review of The Universal PSU Kit. He gives some very good feedback and shows an installation on one of his own PSU Enclosures. | ||

| Line 66: | Line 66: | ||

{{#ev:youtube|YCbQIoLNPYA|400|right|UltimateMicro Universal Apple II Power Supply Kit |frame}} | {{#ev:youtube|YCbQIoLNPYA|400|right|UltimateMicro Universal Apple II Power Supply Kit|frame}} | ||

On April 24, 2016 Chris Torrence from the YouTube channel "[https://www.youtube.com/channel/UCrnCRkPLoXXzTtWX9dBJsnA Assembly Lines]" posted a review of The Universal PSU Kit. He gives some very good feedback and shows an installation on one of his own PSU Enclosures. | On April 24, 2016 Chris Torrence from the YouTube channel "[https://www.youtube.com/channel/UCrnCRkPLoXXzTtWX9dBJsnA Assembly Lines]" posted a review of The Universal PSU Kit. He gives some very good feedback and shows an installation on one of his own PSU Enclosures. | ||

| Line 149: | Line 151: | ||

Capacitors only help keep the output power "clean". They do little in the way of regulation or producing the voltages. Replacing the capacitors is the same as replacing the tires on a car of the same age of your Apple without replacing the engine or transmission. The capacitors don't do any of the "hard" work. All the other parts are responsible and is why you will see burn marks on the PCB from parts over heating but never around the capacitors. | Capacitors only help keep the output power "clean". They do little in the way of regulation or producing the voltages. Replacing the capacitors is the same as replacing the tires on a car of the same age of your Apple without replacing the engine or transmission. The capacitors don't do any of the "hard" work. All the other parts are responsible and is why you will see burn marks on the PCB from parts over heating but never around the capacitors. | ||

{{#ev:youtube|mN71YPoIUqE|350|right|Independent video to better explain how and why it is so hard to test a PSU with basic tools.|frame}} | |||

The disadvantages with rebuilding a power supply: | The disadvantages with rebuilding a power supply: | ||

| Line 161: | Line 163: | ||

It is very hard, if not impossible, to >fully test< a power supply using common bench top tools. Labs use very expensive and high tech equipment specifically made for testing power supplies to certify and calibrate a unit. [http://www.transcat.com/quote-request Transcat] is one such company which not only calibrates your power supply but also documents how and why it fails certain tests. Costs however can rage in to the upper hundreds of dollars which is why most users decide to replace their power supply with something new and known good, or attempt a rebuild. However without the tools to fully test and calibrate a rebuild we're back to just assuming things are working correctly. | It is very hard, if not impossible, to >fully test< a power supply using common bench top tools. Labs use very expensive and high tech equipment specifically made for testing power supplies to certify and calibrate a unit. [http://www.transcat.com/quote-request Transcat] is one such company which not only calibrates your power supply but also documents how and why it fails certain tests. Costs however can rage in to the upper hundreds of dollars which is why most users decide to replace their power supply with something new and known good, or attempt a rebuild. However without the tools to fully test and calibrate a rebuild we're back to just assuming things are working correctly. | ||

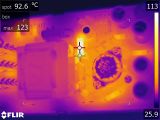

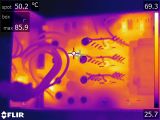

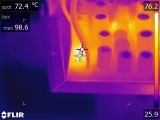

Below are thermal images of your standard Apple II power supply and related temperatures of parts under normal operation. These are the most critical parts, usually involved with regulation, and should ALL be replaced when rebuilding a power supply. The extremely high temperatures are common within all Apple II power supplies, and why we recommend most part are exchanged for similar units but with larger ratings and capacity. None of these parts however are capacitors. | Below are thermal images of your standard Apple II power supply and related temperatures of parts under normal operation. These are the most critical parts, usually involved with regulation, and should ALL be replaced when rebuilding a power supply. The extremely high temperatures are common within all Apple II power supplies, and why we recommend most part are exchanged for similar units but with larger ratings and capacity. None of these parts however are capacitors. | ||

| Line 171: | Line 172: | ||

File:2017-08-15_-_FLIR_of_PSU-4.jpg|Thermal image of end parts of power supply.<br>72.4c / 162F | File:2017-08-15_-_FLIR_of_PSU-4.jpg|Thermal image of end parts of power supply.<br>72.4c / 162F | ||

</gallery> | </gallery> | ||

== KFEST 2016 Session Outlining Project == | == KFEST 2016 Session Outlining Project == | ||

Revision as of 12:41, 21 September 2017

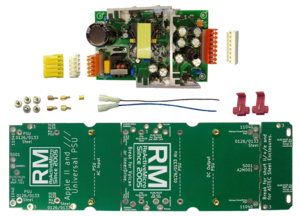

The Universal PSU Kit is a Power Supply replacement designed to be installed by the end user. It is designed to replace the old Power Supply PCB with a new, modern solution while reusing the old Power Supply Enclosure.

As the name implies, the Kit covers the Apple II, II+, IIe, IIgs, and Apple ///. It was conceived, created, and designed by Henry of ReActiveMicro and released for sale to the Apple II Community on April 25th, 2016. The original Universal PCB bore the "UM" Ultimate-Micro logo till August and technically was a collaborative effort with UltimateApple2.

When do you need a new power supply? Good question! Although the answer should be obvious. It is the original, 30+ year old PSU that came with the Apple? Then you need a new one. That simple. How much more do you want or expect from a piece of equipment that was only designed to last a few years at most? Do you really believe Apple designed the power supply to last 30+ years? Most people either don't realize the potential dangers of continuing to use an old PSU or are of the mindset "If it ain't broke, don't fix it." Both can be equally damaging to your beloved Apple II.

It is highly recommended to fully rebuild your power supply or install a Universal_PSU_Kit. You should NOT rely on an original power supply in any case, or even one 'only' 10 years old, as it can be unreliable. It is also very hard, if not impossible, to >fully test< a power supply using common bench top tools. Labs use very expensive and high tech equipment specifically made for testing power supplies to certify and calibrate a unit. Transcat is one such company which not only calibrates your power supply but also documents how and why it fails certain tests. Costs however can rage in to the upper hundreds of dollars which is why most users decide to replace their power supply with something new and known good, or attempt a rebuild. However without the tools to fully test and calibrate a rebuild we're back to just assuming things are working correctly.

Project Status: Complete. In production. Actively sold by ReActiveMicro.

Support: Post on the Discussion page (link above) or email ReActiveMicro Support.

Sales: Visit the ReActiveMicro Store. See the IIe, IIgs, or /// sections for Kits and Cables.

History / Project Revisions

The Universal PSU Kit v1.0 project was released for sale to the Apple II Community on April 25th, 2016. At the date of release ReActiveMicro was still in the process of setting up and testing their new Store and Wiki. So the project became a "collaborative" release with UltimateApple2 in order to have Kits available for the initial delivery release at KFEST 2016. After KFEST the rest of the pre-orders were shipped to buyers.

Up till August 2016 the Ultimate-Micro.com Store was the only vendor who distributed the project. Then as part of ReActiveMicro.com's full return from hiatus with their new Store and Website release they took over sales and distribution to better serve and support the Apple II Community. At this time the Universal PCB was also revised with the ReActiveMicro logo.

On May 7th, 2017 ReActiveMicro re-released the Universal PSU Kit as v1.1 at a new lower price and with a new Universal PSU unit. This new Universal PSU is equivalent to the v1.0 unit.

Features Of The Universal PSU Kit

- Fits all standard Apple II and /// Power Supply Enclosures. (all parts included, user supplies household tools)

- Meets or surpasses all Apple II and /// power requirements.

- Modern PSU design.

- Standard 2 year warranty.

- Universal PSU operates on a wide range of input power: 90-264VAC, 47-63Hz.

- On-board Power LED shows when AC is applied to the Universal PSU and is working.

- Constant Voltage design

- Fast Power Reset: No more “hung” systems or need for long off periods and waiting before turning back on.

- Interchangeable DC Output Cable for II/+/e/gs/III. One PSU can support all!

- Runs cool/low heat output: Operates cooler than the old Apple II PSU.

- Cleaner and more consistent power than the old Apple II PSU.

- More efficient than old Apple PSU: Consumes 1.6A at 100v, 1A at 230v, 63W max at full output: +5v 6A, +12v 3A.

- Fused AC Over Current/Over Voltage/Surge protection.

- DC Over Voltage protection (active crowbar design), and auto restart.

- Fully UL/CE Certified and tested design.

- All units fully stress-tested/burned-in at 90% loading before shipping.

- Kit is “reversible”. You can downgrade your Enclosure back to its original state if desired in the future.

Reviews

On April 24, 2016 Joe Strosnider posted a review of The Universal PSU Kit. He gives some very good feedback and shows an installation on one of his own PSU Enclosures.

On April 24, 2016 Chris Torrence from the YouTube channel "Assembly Lines" posted a review of The Universal PSU Kit. He gives some very good feedback and shows an installation on one of his own PSU Enclosures.

Project Progression: Inception

When Henry from ReActiveMicro first returned to the Apple II he found several systems obtained had Power Supply issues or wouldn't power on. Some systems appeared to work but had very intermittent problems. This caused several issues with testing and projects.

Henry started by diagnosing most issues back to the Power Supply. These units were about 20 years old at the time, and were only designed to last 5 at the most. A lot of the parts responsible for voltage regulation were either dried out or had been over heated. Some capacitors even showed signs of being swollen. Any bulging top means that they are damaged, will not function properly, and should be replaced immediately.

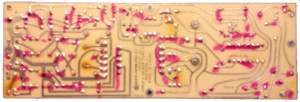

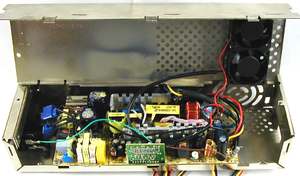

During his research Henry found that all Apple Power Supplies were designed very poorly. Parts were always under sized for the job they were required to do. This led to many parts overheating. Some even get so hot as to discolor the fiberglass PCB (pictured right). Many Power Supplies exampled showed signs of extreme over-stressing. This isn't as much of an issue with lightly loaded systems, however those systems loaded with peripheral cards or high-drain devices may see more apparent issues or even Power Supply failures.

So Henry was faced with two options: Rebuild the 20+ year old Power Supply Unit (PSU), or find a replacement which could be mounted in the Apple II and Apple ///.

- Examples Of Overheated PCBs

-

Rear of common PCB damage.

-

Front of common PCB damage.

Project Progression: Rebuild

Henry first started by rebuilding old Apple II PSU boards in 2005. This however posed some issues since there were many variations of the PSU boards. Each board has at least 50 parts. Some parts are hard to access and remove. Other parts are so old they are no longer produced and need to be cross referenced with newer parts. And worst of all, most parts are under sized and need to have their ratings increased so they are no longer being over-stressed.

The time involved on a PSU PCB rebuild is in the range of 5 hours. Some of the replacement parts can also be costly and hard to find. The amount of time and effort needed to even rebuild 5 PSUs just didn't seem worth it after a while. A major issue remained however. The heart of the PSU still wasn't being replaced - the Step-down Transformer. This was the one part which is no longer produced. There is some New Old Stock (NOS) to be found, however it is not new and is still 20+ years old.

The problem here is the copper wires inside the Transformer are coated with a very thin insulating coating. After years of oxidation and wear of heating up and cooling down cracks form which leads to the Transformer shorting out and usually lots of smoke and even fire. Worse than this however is it can lead to the Transformer outputting voltages far in excess of what they should be. This is the primary cause of damage to motherboards and peripherals. Parts will be over-stressed due to the unregulated voltages output by a dying Transformer. If this doesn't lead to instant failure of an IC, then it will weaken it which leads to an early demise or intermittent issues. The Transformer doesn't need to fail for such damage to be caused. Many of the regulating Diodes can also fail and cause damage in the same way.

Project Progression: ATX PSU

In 2006 Henry changed his approach from repair to replacement. The new concept would be to be remove the old Apple PSU PCB and replace it with a new ATX PSU PCB.

Henry found a U2 size ATX Power Supply (now called Mini ITX) which came standard with the -12v and -5v outputs. Most Power Supplies no longer supply -5v, which the Apple II requires. This "U2" size was however a perfect fit for a replacement PSU PCB option. This approach however had some issues.

First, Henry would need to disassemble the ATX Power Supply and remove the ATX PCB. Next, the bare ATX PCB didn't mount to the Apple II Enclosure's mounting points. Apple's Enclosures don't have any standardized mounting points inside. These mounting points change from model to model. This forced Henry to modify the Apple PSU Enclosure - something he is against. He would need to remove or add standoffs in order to firmly secure the new ATX PCB inside the Enclosure. Lastly, connecting the Apple II DC Output Cable to the ATX PSU proved time consuming. In fact the whole upgrade procedure would take about 2 hours to complete. This coupled with the cost of a Server grade U2 ATX Power Supply proved an expensive option for most users.

After about a year of selling the ATX replacement they were discontinued till a better option could be found.

Project Progression: Universal PSU Kit

In 2015 Henry revised the Power Supply project after experiencing issues in a project that once again turned out to be power related. After some more research Henry learned that ATX was not a good solution for the Apple II. It poses several issues. For example the "IOmin" values are never met, and the +3.3v output is not used. Some ATX PSUs also have a +5v VSB output that isn't used in the Apple II. And most ATX units today don't have -5v anymore, so we are forced to make it.

Not meeting the IOmin values can cause something as simple as reduced power or voltage regulation, or even the ATX PSU not turning on. It can also lead to things a lot worse such as wild swings in output voltages far beyond what is normal and the PSU overheating or burning up. Issues can and will be inconsistent and are affected by temperatures, humidly, how "clean" the AC input power or voltage is, and loads. An ATX PSU is NOT the right choice for an Apple II in ANY situation.

An ATX PSU is not designed to operate with a load as low as the Apple II. The Apple II only requires about 15w of power. It's like a Buggy: Dependable, easy to repair, low cost, easy to understand and add to. The PSU it requires is only a small work animal, like mule or horse. In comparison, an ATX PSU starts at the low end of 150w and go up in to the thousands of Watts. They are designed to power much bigger power hungry and complex systems. The Buggy is perfect for a local trip to the corner store, and the Rocket is a better choice when trying to reach the Moon. It is always best to match the tool to the job. You don’t want to use a chain saw to widdle a toothpick. Nor do you want to use a pen knife to cut down a 200 year old oak tree.

- Your Apple II Design Verses Connected To An ATX PSU

-

Your Apple II/III's Design

-

Your Apple II on ATX (not the right tool)

So Henry thought about the issues at hand and decided a replacement PSU PCB is still the best option. He looked in to the possibility of creating a replacement Enclosure, however at the time the costs were still very prohibitive in small runs.

The new PSU needs to fit in the existing Apple II Power Supply Enclosure, have quad voltage output (-5v, -12v, +5v, and +12v), have the correct Amperages to work in all Apple II systems (-5v: 0.25A, -12v: 0.25A, +5v: 4A, and +12v: 2.5A), accept universal AC voltages and frequencies, have no need to modify the Apple II Enclosure in any way, and most importantly - still be in production. Henry could produce a clone of a past production model if needed, however devices that deal with main voltages (110V AC or more) usually are built in special ways to be as safe as possible. This could pose some assembly issues.

The same mounting issues encountered before with the ATX PCB would still be an issue with the new PSU. Henry however had a new idea to use a custom PCB that would mount inside the Apple II Enclosure which would then allow the new PSU to mount to the PCB. He then started measuring all known Enclosures for the Apple II and /// to produce the "Universal PCB". As it's name implies the PCB can mount in to all Apple II Enclosures and even the /// PSU Pan.

Henry then discovered two possible PSUs designs that would work, were a perfect match for voltages and current requirements, and were physically able to fit inside the Apple II Enclosure. Best of all one of the options was still being actively produced and available in bulk!

If Henry was correct, he should be able to combine all the parts for the Universal PSU Kit in such a way that even the End User could safely install it. This then became the Active goal of the project.

Capacitor Kits And Rebuilds

Some users have purchased and installed "Capacitor Kits" and even replaced some critical parts like Diodes. This is better of course, but sorry to say you still need to FULLY rebuild your power supply, or more simply install a new power supply.

At the the heart of the power supply is the Step Down Transformer. Did you replace this? We know you couldn't have since they don't make them anymore. And if you did, then it was old stock that was also 30 years old. When a transformer is operated under ANSI / IEEE basic loading conditions (ANSI C57.96), its normal life expectancy is about 20 years of use. This is an industry specification and NOT an opinion.

The problem here is the copper wires inside the transformer are coated with a very thin insulating coating. After years of oxidation and wear of heating up and cooling down cracks form which leads to the transformer shorting out and usually lots of smoke and even electrical fire. Worse than this however is it can lead to the transformer outputting voltages far in excess of what they should be. This is the primary cause of damage to motherboards and peripherals. Parts will be over-stressed due to the unregulated voltages output by a dying transformer. If this doesn't lead to instant failure of an IC, then it will weaken it which leads to an early demise, or worst of all intermittent issues. Luckily transformer failure isn't as common as other issues are, however when it happens it can be far more destructive.

Capacitors only help keep the output power "clean". They do little in the way of regulation or producing the voltages. Replacing the capacitors is the same as replacing the tires on a car of the same age of your Apple without replacing the engine or transmission. The capacitors don't do any of the "hard" work. All the other parts are responsible and is why you will see burn marks on the PCB from parts over heating but never around the capacitors.

The disadvantages with rebuilding a power supply:

- The hours of time and tools required to fully rebuild.

- The knowledge and tools needed to fully understand when there is an issue or when all is working correctly.

- The time required to make a Bill of Materials to place a parts order.

- The ability to source or cross reference parts when originals can't be found.

- The ability to source or cross reference better rated parts for increased life and reliability.

- The knowledge to cross reference and know the difference between parts and why one part is better or required compared to others.

- Certifying and calibrating a power supply is VERY expensive.

It is very hard, if not impossible, to >fully test< a power supply using common bench top tools. Labs use very expensive and high tech equipment specifically made for testing power supplies to certify and calibrate a unit. Transcat is one such company which not only calibrates your power supply but also documents how and why it fails certain tests. Costs however can rage in to the upper hundreds of dollars which is why most users decide to replace their power supply with something new and known good, or attempt a rebuild. However without the tools to fully test and calibrate a rebuild we're back to just assuming things are working correctly.

Below are thermal images of your standard Apple II power supply and related temperatures of parts under normal operation. These are the most critical parts, usually involved with regulation, and should ALL be replaced when rebuilding a power supply. The extremely high temperatures are common within all Apple II power supplies, and why we recommend most part are exchanged for similar units but with larger ratings and capacity. None of these parts however are capacitors.

-

Example of Apple II power supply.

-

Thermal image of front parts of power supply.

92.6c / 199F -

Thermal image of middle parts of power supply.

50.2c / 122F -

Thermal image of end parts of power supply.

72.4c / 162F

KFEST 2016 Session Outlining Project

Henry from ReActiveMicro presented the "Universal PSU Kit" sessions while at KFEST. His Ultimate-Micro partner, Anthony Martino, introduced the session.

Support: Connect AC To The Universal PSU

The Universal PSU is powered by 90-264VAC, 47-63Hz. Under full 63w load it consumes 1.6A at 100v, and 1A at 230v.

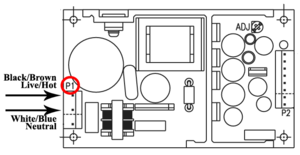

To connect the AC power first local the "P1" connector on the Universal PSU (see picture on right).

Connected the wires as shown. The Black or Brown (Live) wire will connect on the end of the P1 connector closest to the large capacitor. The White or Blue (Neutral) wire will connect to the middle of the P1 connector. Ground is supplied my the Apple II's enclosure. You can however connect it to the PSU PCB mounting screw or on the end of the P1 connector closest to the PSU PCB mounting screw.

Support: Connect DC Output Cable To The Universal PSU

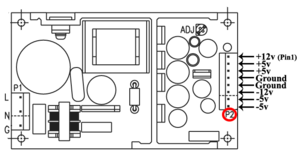

The Universal PSU will output 63W max at full load: +5v 6A, +12v 3A.

To connect the DC Output Cable first local the "P2" connector on the Universal PSU (see picture on right).

Typically the colors Apple for the II used are as follows:

- +12v: Yellow (sometimes White with Orange Stripe) (Pin 1 on P2)

- +5v: Orange (Pin 2 or 3 on P2)

- Ground: Black (Pin 4 or 5 on P2)

- -12v: Green (sometimes White with Blue Stripe) (Pin 6 on P2)

- -5v: Blue (Pin 7 or 8 on P2)